Before a product reaches consumers, it starts as an idea. Engineers must shape, test and refine it long before production begins. This is where the notion of product prototyping came to pass. More than a rough draft, it connects vision to reality, allowing teams to validate function and feasibility.

However, industries are growing more competitive, which means timelines are shrinking. Therefore, designers and engineers have needed a smarter way to implement this process, and technology has become essential in meeting this need. The tools used to prototype today are helping innovators reduce risk and bring better products to market in record time.

The value of prototypes in product development

Prototypes are proof of concept. Whether physical or digital, they allow companies to identify flaws and improve design decisions before committing to full-scale production. Essentially, they are tools for reducing uncertainty, encouraging iteration, revealing blind spots, and helping teams build more confidently.

This stage is also critical, as innovation is accelerating across every sector. According to McKinsey & Company, an estimated $30 trillion in corporate revenue over the next five years will depend on products that have yet to reach the market 1. To stay ahead, prototyping has become central to helping companies avoid costly errors.

Prototyping supports companies in several ways:

Reduces time to market by uncovering design flaws and inefficiencies early in development.

Minimizes production costs by preventing expensive last-minute changes.

Improves cross-team collaboration by offering a visual, testable model.

Supports user testing and feedback to better align with customer expectations.

Increases investor and stakeholder confidence through tangible evidence of progress.

Prototyping provides the space to experiment and the data to strategize. Overall, it lays the foundation for every successful product journey.

Why you should not skip product prototyping

Pushing a product into development can be tempting, given tight deadlines and budget constraints, but skipping the prototyping phase often leads to far greater setbacks. Without this critical step, teams risk overlooking flaws, misaligning with user needs, and investing heavily in ideas that do not work in practice.

Creating a prototype also reduces the chance of someone stealing the intellectual property, keeping the idea protected2.. Documenting it through provides the records to support patent applications and strengthen legal protections.

How technology drives prototyping success

Technology has become essential to prototyping efficiently and effectively. Modern tools help teams turn abstract ideas into workable solutions faster than ever, making them business-critical.

For instance, the engineering, research and modeling sector held the largest share of simulation tools. According to market research, the global market for simulation software was estimated at $23.56 billion in 2024 and is predicted to reach $51.11 billion by 2030 3. This increased investment rate shows the growing demand for these tools because they enable more agile development processes.

Technology plays a large role in prototyping, benefiting companies in the following ways:

Faster iteration cycles.

Improved accuracy of modeling.

Cost savings.

Increased innovation.

Essential technologies powering today’s prototyping

The following tools make simulation, testing, and refining designs more precise and collaborative.

Computer-aided design (CAD) and simulation software

CAD platforms give designers and engineers a shared space to visualize and modify models in 3D. When paired with simulation features, they help teams stress-test designs under real-world conditions before manufacturing a single part. These simulations allow for the detection of weak structural points or material failures and reduce the number of physical prototypes necessary.

For instance, an automotive team may use simulation software to find stress points in a car's suspension system. This allows them to optimize the design before building any physical parts.

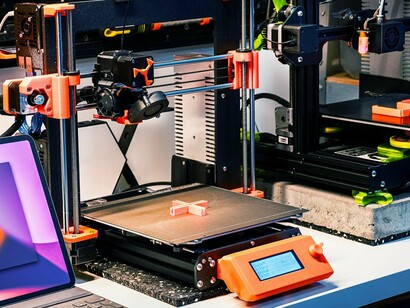

3D printing and additive manufacturing

3D printing was once meticulous and expensive. Yet, thanks to additive manufacturing, creating physical models can now happen more quickly. These tools allow for rapid iteration and functional testing of everything from medical devices to consumer goods. The ability to test form, fit, and usability in real-world environments accelerates production cycles while reducing design-related waste.

AI and machine learning in prototyping

Artificial intelligence (AI) is reshaping how teams create prototypes by automating repetitive tasks and providing data-driven design recommendations. One example involves a product team integrating AI to generate prototypes to improve collaborations between design, product, and engineering departments.

They used AI to create early-stage mockups based on previous project patterns and requirements. With intelligent tools, they cut creation time by 95% and saved over $50,000 in engineering waste4.

Tech-forward tips to prototype products like a pro

Teams succeed when they use these tools the right way. Implement these tips to make the most of your prototyping process.

1. Start with the end user in mind

Even with advanced technology, prototyping can still fall flat if it does not incorporate real user needs. The most effective prototypes focus on the end user in terms of function and experience.

Before jumping into tools or specs, consider who the product is for, what problems it solves, and how users will interact with it. For example, if you are designing a fitness tracking app for older adults, the prototype should prioritize readability, simple navigation, and larger tap targets to match their needs.

Use prototyping to map user flows and simulate key interactions. These tasks ensure teams catch friction points early. Platforms like Figma or Adobe XD make it easy to create quick, testable mockups that reveal how intuitive a product is.

2. Use rapid prototyping to iterate faster

Speed is often the difference between a breakthrough and a missed opportunity. Rapid prototyping allows teams to test, refine, and retest ideas quickly, shortening development cycles and reducing costly delays.

3D printing and modular design platforms enable rapid prototyping by letting teams produce physical models in hours instead of weeks. In software development, low-code and no-code tools can create functional mockups for immediate user testing.

The goal of faster iterations is to fail fast, learn quickly, and improve with each cycle. Rapid prototyping brings you closer to a product that works in real life.

3. Employ digital prototyping tools for complex systems

The more functionality a product has, the greater the need for digital prototyping. These solutions allow teams to simulate user interactions and backend processes before development begins. They also support version control and feedback tracking so distributed teams can stay aligned across iterations.

A few tools include Autodesk Inventor, Siemens NX, and PTC Creo. Each offers advanced modeling and simulation capabilities that accurately replicate real-world use cases. Platforms for UX/UI-heavy products also exist, like Axure or ProtoPie, which go beyond static visuals to prototype logic and dynamic content.

4. Choose the right fidelity at the right time

Some may believe every prototype should be high-tech or high-fidelity from the start. However, to save time and conserve resources, you should choose the right level of detail at each stage.

Low-fidelity prototypes include paper sketches or wireframes and are ideal for early-stage ideas because they allow teams to test layouts, flows, and basic concepts before investing5. As ideas mature, transitioning to high-fidelity prototypes makes sense for refining design and user experience.

The key is to match fidelity to purpose. Use low-fi to explore ideas and gather broad feedback — implement high-fi to validate design decisions and test real interactions. Jumping to high-fidelity too soon can result in wasted effort, while sticking with low-fi for too long can limit insight.

5. Document every step

Documentation is imperative because skipping it can be costly in the aftermath. Capturing each stage of the prototyping process preserves ideas and prevents duplicated effort. It also builds a clear trail of decision-making for future reference.

This is especially important when working across departments or preparing for patent filings and regulatory reviews. Version histories, annotated design files, and testing logs provide accountability, helping teams stay aligned during handoffs. Many prototyping platforms offer version control and changelogs to streamline this process.

Make product prototyping a tech-driven habit

Prototyping a product offers several advantages in a competitive market. A well-executed one gives teams the insight to build smarter, from reducing development costs to improving product-market fit.

Yet, with the market moving so fast, companies need a way to test and refine their ideas more efficiently. Technology is the key to achieving more in less time, so make it part of your process for lasting innovation. Regardless of your business or product type, tech-driven prototyping builds a better process that drives long-term success.

Notes

1 Digital Twins: The Key to Smart Product Development at McKinsey & Company.

2 How to Create a Product Prototype at SIMTEC.

3 Simulation Software Market Size, Share & Trends Analysis Report at Grand View Research.

4 Using AI-Created Prototypes to Align Design, Product, and Engineering by Jeremy Belcher.

5 High-Fidelity vs Low-Fidelity at GeeksforGeeks.